TIG – MIG WELDING

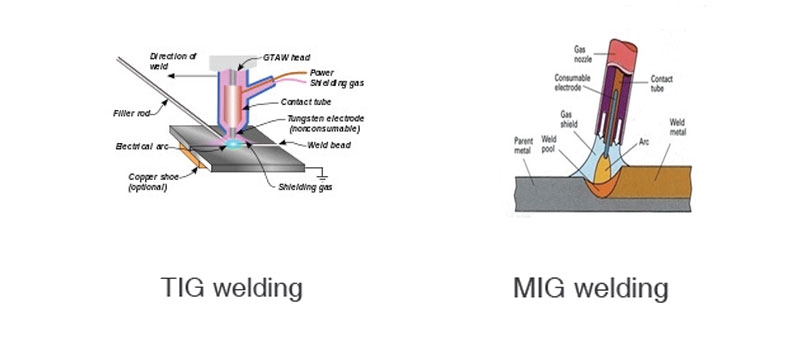

TIG WELDING

TIG welding is one of the most popular methods, provides high-quality joints, but requires highly skilled operators.

One of the main advantages of this technology is that the filler material in the welding melt is independent by the contribution in the thermal welding, unlike what happens in the flush welds or in consumable electrode. The TIG procedure is particularly suitable when they have to be welded small thicknesses of material, as low as a few tenths of mm, however it is not possible to weld thicknesses greater than a few mm (2-3 mm for steels) with a single pass (therefore, in general, is not used for welding thicknesses greater than 5-6 mm), then, considering the low productivity, it is often used to make the first pass of a joint, while the filling is carried out successively with procedures to higher productivity. Given its characteristics, the process can be used in any position and can be used for continuous welding or spot welding.

MIG WELDING

The MIG / MAG process is a continuous line procedure in which the protection of the weld pool is ensured by a cover gas, which flows from the torch onto the workpiece. The fact that it is a continuous wire ensures high productivity at the same process, and the presence of gas at the same time allows operation without slag. The MIG / MAG welding is used when requiring high productivity and sufficient flexibility. With this technology it is possible to weld steel is austenitic and ferritic alloys of light metals (Al and Mg), copper alloys, nickel alloys, and titanium alloys.